Grow your own material !

My research interests have always been related to material exploration. While I was searching for new materials to explore, I stumbled upon the idea of growing one’s own bio-materials, and was completely fascinated by it: What if in the near future, a new generation of products is grown by microbes, instead of using materials as we find them?

With that in mind, I looked into regenerative materials created by an increasingly popular fermented drink – kombucha. Kombucha is made from a fermentation process using tea, sugar and “SCOBY”, a symbiotic culture of bacteria and yeast. During this process, a by-product made from cellulose nanofibrils is generated and floated to the surface of the beverage, which creates a leather-like material when dried. Designers are currently exploring the potential of this bio-material as an alternative to ethically problematic use of animal leather. An example is the work of Suzanne Lee. Suzanne is a pioneer fashion designer in the field of biotechnology in textiles, and her work has proven the possibility of adopting biomaterial into clothing.

Fig 1: Biocouture by Suzanne Lee

Bacteria-grown material is not difficult to create at all. I will share my experience and recipe so you can also try to do it at home. The recipe I am sharing is similar to brewing kombucha tea, except some ingredients are modified to maximize the cellulose production.

Recipe:

1 x SCOBY (you can shop from here)

1 x large plastic container

5 x breen/black tea bags

1 cup x white sugar

A heating mat (80 °F / 27 °C)

Cheese cloth + rubber band / clips

Water (volume adjusts to match container size)

Fig 2: Cultivating the bacteria to produce bio leather-like material (Project credit: Suzanne Lee)

Step 1: Find a container that is big enough to fit your SCOBY in.

Step 2: Bring the water to a boil (match the volume to fill half to three quarters the height of your container). This process is to purify the water and eliminate living bacteria that can contaminate your SCOBY.

Step 3: Remove water from heat. Add all tea bags and sugar. Stir well until all sugar is melted. Wait until tea has cooled down to room temperature as boiling water will kill the SCOBY.

Step 4: Put a heating mat under the container to keep the culture at the optimum temperature. Sterilize hands, then pour the tea into the container. Add SCOBY into the tea. Cover the container with the cheese cloth and secure it with either clips or a rubber band.

Fig 3: Dried bio-material from SCOBY

Once everything is set up, let the culture grow for two to four weeks. Over time, a layer of culture will appear on the surface of the liquid, which grows thicker over time and can become paper or leather-like when dried into sheet form. When harvesting the material, make sure to rinse it with thoroughly with water to remove the sugar and other impurities.

Growth manipulation:

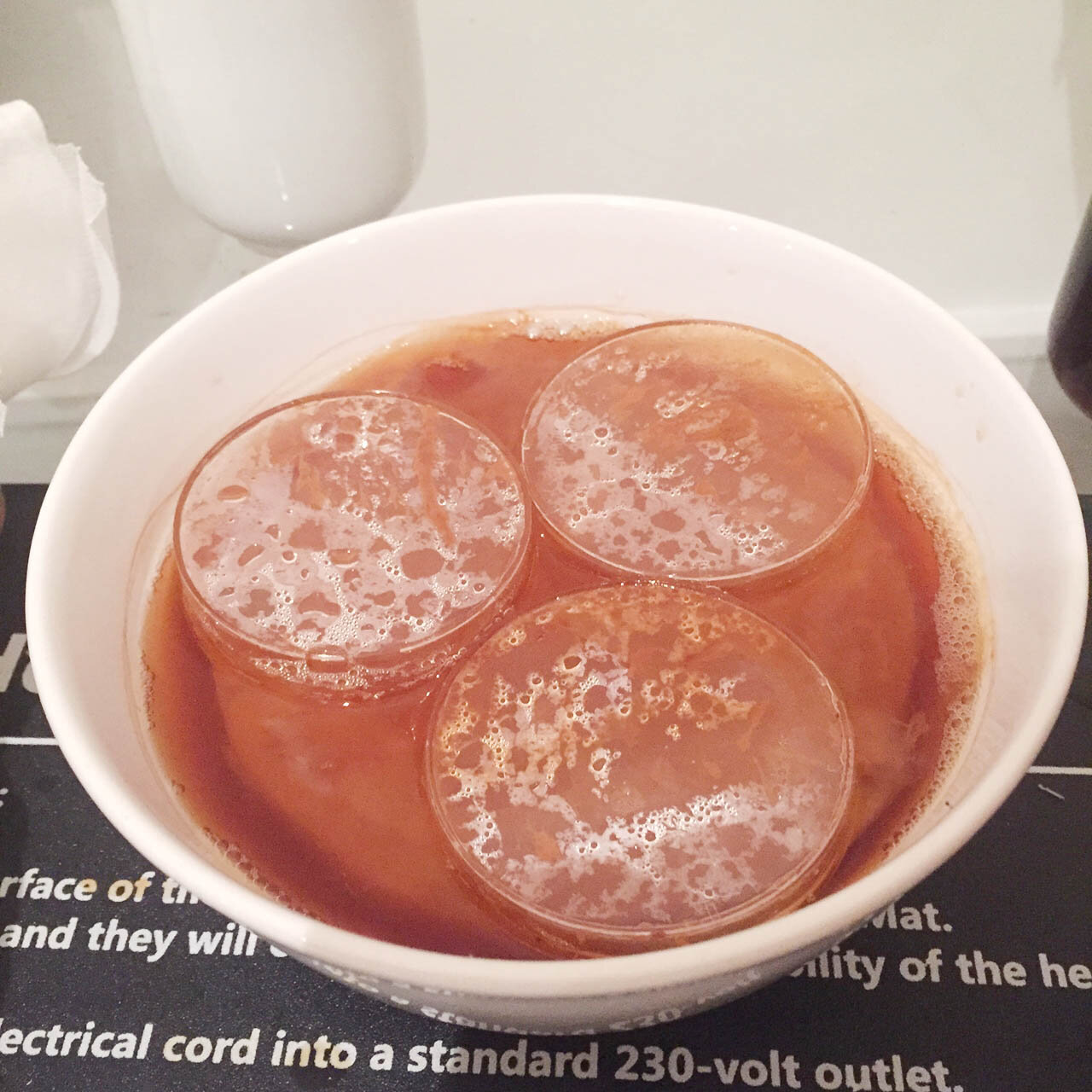

Figure 4a: Manipulating bacterial growth through controlling oxygen supply. The area covered with petri dishes has less oxygen supply.

Figure 4b: The culture grew thicker in areas exposed to air.

Like many cultures, SCOBY depends on oxygen for its life-cycle. For my own research project, I looked into ways in which one can manipulate the bacteria growth. By controlling the oxygen available in specific areas, I could change the rate of growth, hence generating controlled patterns on the surface.

Fig 5: Pattern generated by bacteria through controlling oxygen supply

Colouring:

Fig 6: Extracting natural dye from organic waste

If you were interested in dying the material, you could also experiment with natural food dye methods from fruit and vegetable waste. One way to extract the colour is by boiling the organic waste with water. The tea you use for growing the culture will also affect the colour. Green tea will give a lighter tone to the bio-material, which will make it easier to add an extra layer of colour dye.

Figure 7a: Extracting natural dye from red cabbage stems

Figure 7b: Extracting natural dye from pomegranate peels

It is worth noting that after introducing food dye into bacteria culture, it should be dried as soon as possible as the organic dye and moisture will encourage mold to grow and contaminate the material. Once the material is fully dried, it will become darker in colour and more leather-like. Now you can explore the possibilities of creating forms and products with them!

Fig 8: Dried Bio-material

Image references:

Fig 1: Biocouture by Suzanne Lee [Online], available at <https://stamps.umich.edu/stamps/detail/suzanne_lee>

Fig 2: Cultivating the bacteria to produce bio leather-like material [Online], available at <https://www.youtube.com/watch?v=Ek3v9XTgnsY>

Fig 3: Dried bio-material from SCOBY (own image)

Fig 4: Manipulating bacterial growth through controlling oxygen supply (own image)

Fig 5. Pattern generated by hbacteria (own image)

Fig 6. Extracting natural dye from organic waste.(own image)

Fig 7. Extracting natural dye from organic waste.(own image)

Fig 8. Bio material from bacteria. (own image)